Hazardous Area Transformers

Our hazardous area manufacturing team offer an extensive range of ATEX, IECEx and FM certified transformers. Our transformer range is used in pharmaceutical, offshore, chemical and petroleum sectors.

Hazardous Area Transformers

As your trusted experts, we specialise in the design and manufacture of Hazardous Area Transformers.

R Baker (Electrical) Ltd has unrivaled expertise in the manufacture of ATEX Transformers. Our Hazardous Area Team understand precision engineering is critical when working in Zone 1 and Zone 2 environments.

Our range of Hazardous Area Transformers are custom built according to IECex standards. We are leading designers and manufacturers of intrinsically safe and explosion proof equipment. Having experience in petrochemical, pharmaceutical and oil & gas we are able to offer the solution you need.

Manufacture

We are the leaders in transformer design and manufacturing. We have the design capabilities to manufacture and meet the requirements for all different ATEX/IECex hazardous areas.

ATEX Transformer Design

Our design team will liaise with you to determine the specific ATEX zone and electrical requirements. This will determine the transformer design and enclosure specification. Each solution is custom designed to ensure you get the best possible solution.

Lead Times

Transformer Rating

Our standard ATEX transformer range are generally double wound and range from 500VA to 15kVA. Custom larger solutions can be designed but this dependent on requirements.

Standards

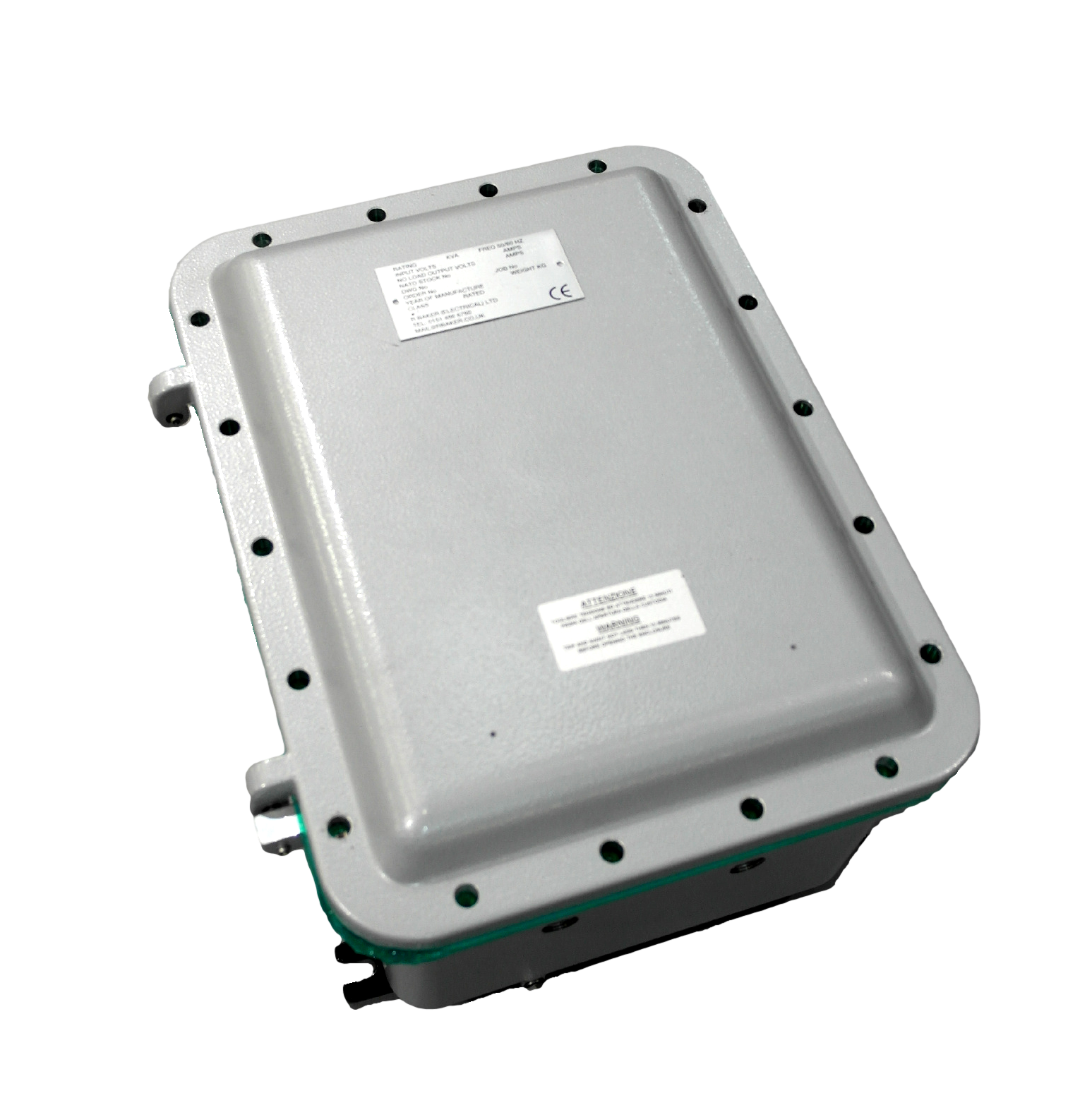

ATEX Transformers are built using international transformers standards. Our Hazardous Area range comes with comprehensive documentation. This will include regulatory documents for ATEX, IECEx, FM etc. and EC declarations of conformity.

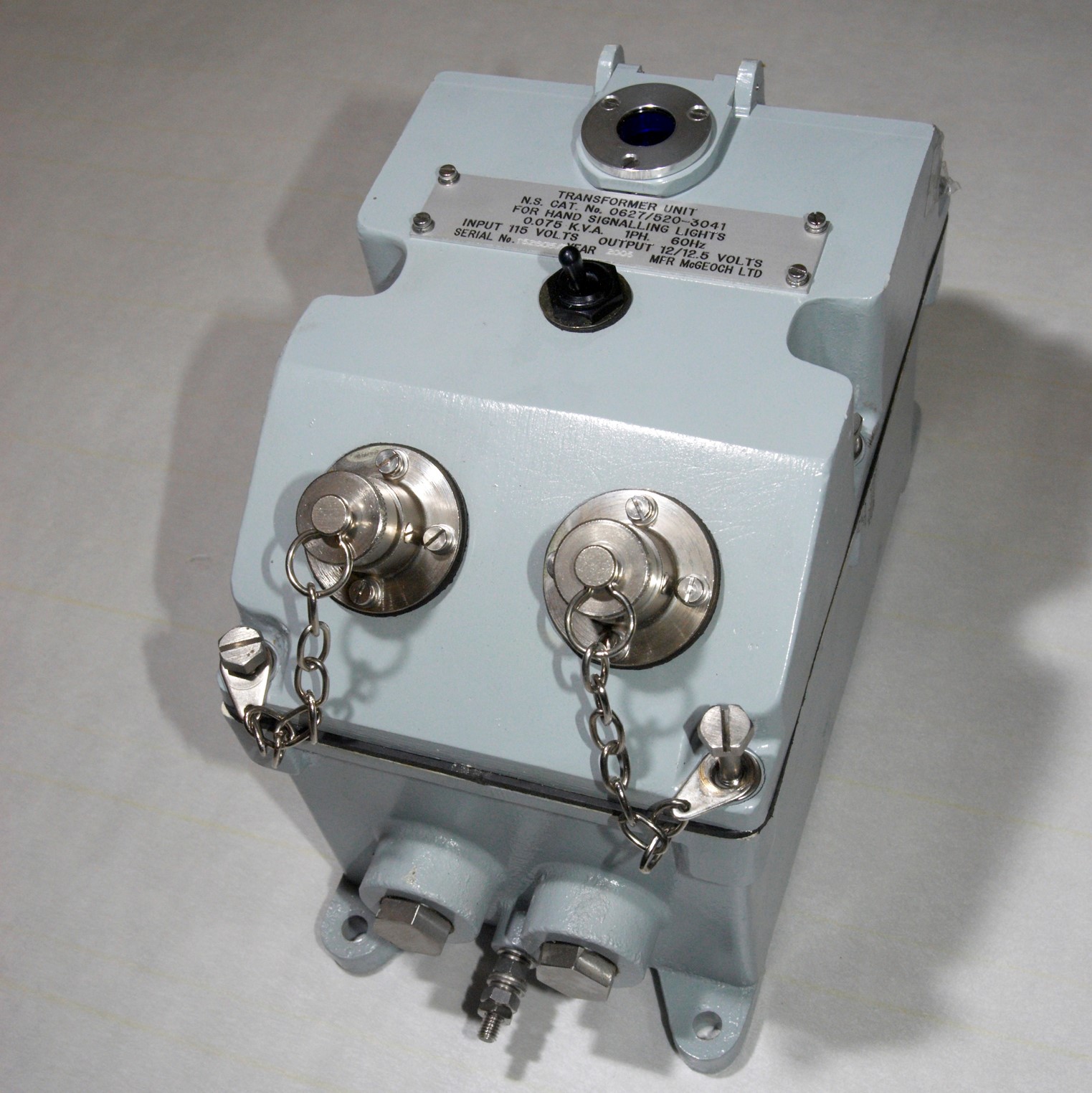

Enclosure Style

We offer a range of Ex d solutions, as well as custom built solutions. We offer a variety of sizes to suit every purpose, with a choice of either hinged (EJB) or threaded (GUB) lids.

Contact an expert

Our in-house design team can offer advice on intrinsically safe and explosion proof transformers. We have a wealth of experience working in potentially explosive environments. However unique your application is, our team are here to help.

Transformer Enclosures

For unique specifications we offer different rates and structural design for hazardous area transformer enclosures. These enclosures are suitable for those industries where potentially explosive environments exist. This includes; chemical, petrochemical and pharmaceutical industries and offshore ship industries.

To learn more about our hazardous area services also click on the links below for our social media feeds.

FAQ’s

Here you can find the answers to simple hazardous area questions before you make an enquiry with us.

We understand each project is bespoke so please feel free to contact us on 0151 486 6760.

Do we offer free advice?

Our in-house team are ATEX and transformer design experts. We are here to offer the best possible advice in the industry. Call today to discuss your requirements; 0151 486 6760.

Our largest kVA rating

We have the engineering capabilities to manufacture ATEX/IECex hazardous areas transformers up to 15kVA.

Where are we based?

R Baker (Electrical) Ltd are located in Liverpool, UK. We are perfectly positioned to offer a worldwide service.

ATEX transformer quotes

Quotes for explosion proof equipment tend to take longer to produce than our standard 24 hour turnaround. This is due to the unique application and design process.

Lead times

Lead times for explosion proof can depend on your specification. The average lead time is 6 weeks from order.

Hazardous Area range

Our standard enclosure are EJB and EJB INX. This range includes steel and stainless steel enclosures.

Case Study –

NOV Wellbore Technologies

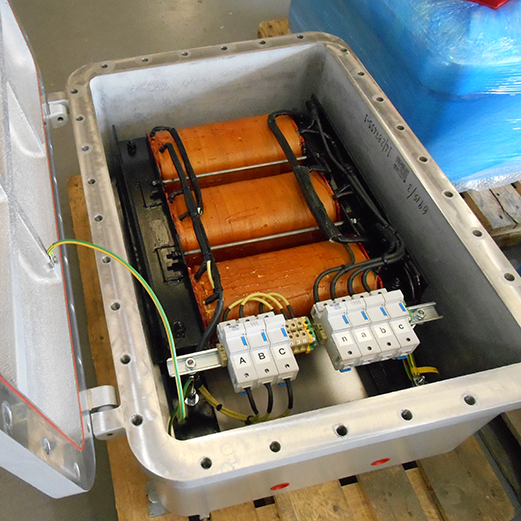

We were tasked by NOV Wellbore Technologies to manufacture two transformers for use in Zone 1 environments. Our specialist ATEX team designed a 30kVA and 15kVA ATEX certified transformers.

Both Zone 1 transformers were air cooled isolating transformers for use on an offshore platform. The Hazardous Area Transformers were enclosed in stainless cases, custom-made to meet the offshore requirements.

This project was time sensitive and needed to be turned around in a 4-week period. Due to maintenance schedules this deadline had to be met. This was achieved even though design had to passed through client design approval processes.

Accreditations & Memberships

Call our team on 0151 486 6760

Get in touch...

Call us on 0151 486 6760

Address:

R Baker (Electrical) Ltd

Evans Road

Speke

L24 9PB